Tech’s Essential Role in Food Safety

The Dirt

With funding for federal food safety programs tightening, it's time to lean into the science-backed tools already at our disposal—like food irradiation, AI monitoring, and high-pressure processing—to ensure safe food for all. The future of our food supply depends on it.

Global Food

Tech’s Essential Role in Food Safety

The Dirt

With funding for federal food safety programs tightening, it's time to lean into the science-backed tools already at our disposal—like food irradiation, AI monitoring, and high-pressure processing—to ensure safe food for all. The future of our food supply depends on it.

Each year, the CDC estimates that 48 million Americans are affected by foodborne illness, resulting in over 128,000 hospitalizations and 3,000 deaths. Behind those numbers are real people—a child at lunch, a grandparent at dinner, a parent preparing a family meal—who simply expected their food to be safe.

Who’s Watching Our Food?

Meanwhile, the infrastructure designed to protect that safety is facing mounting pressure. Recent cuts from the new administration to the FDA’s food safety programs are compounding challenges for inspection teams already stretched thin. State public health labs are grappling with outdated technology and staffing shortages. The result: slower investigations, fewer routine checks, and an increasing reliance on food producers to self-monitor.

It only takes one outbreak to expose the vulnerabilities in our food system.

These outbreaks happen on a fairly regular basis:

In May 2025, there was a salmonella outbreak with cucumbers affecting consumers in Florida. In 2024, the U.S. faced a string of serious foodborne illness events: a Listeria outbreak linked to deli meats claimed 10 lives across 19 states; Salmonella-contaminated cucumbers sickened more than 500 people in two separate incidents; and a nationwide recall of Yu Shang Food products followed another deadly Listeria case.

Why Tech Is Essential in an Era of Shrinking Oversight

Yes, the scale of foodborne illness is alarming—but it’s also important to consider the context. Every day, hundreds of millions of Americans eat multiple meals, resulting in billions of opportunities for something to go wrong. That the vast majority of those meals are safe is a credit to the resilience of our food system. But that resilience is not guaranteed.

As the system grows in scale and complexity, so must our approach to protecting it. Total elimination of risk is statistically impossible, but we can drive that risk down to the lowest level possible through smarter practices, stronger technology, and more coordinated oversight. That means moving beyond manual spot-checks and embracing proven tools already at our disposal, from rapid DNA sequencing to AI-based monitoring and smart traceability platforms.

Food safety isn’t the responsibility of regulators alone. It’s a shared commitment between government agencies, industry leaders, technology developers, and, yes, consumers themselves. In a system this vast, progress from constant, deliberate improvement.

The Tools That Can—and Should—Protect Us

Today’s food system is more complex, globalized, and fast-moving than ever before.

Fresh berries from Chile, seafood from Vietnam, baby spinach grown in California—all of it might travel thousands of miles, change hands a dozen times, and still land safely on your plate within days. That’s an incredible feat of logistics and science, but also a reminder that our food chain is vast, intricate, and increasingly difficult to monitor with traditional tools alone.

Behind the scenes, a suite of cutting-edge technologies is quietly revolutionizing the way we protect our food—from AI algorithms that scan for contamination risks before a human could spot them, to biosensors embedded in packaging that alert us when a product has spoiled, to blockchain systems that trace a head of lettuce back to its exact harvest date and field location in seconds.

These tools aren’t speculative or futuristic—they’re here now. They’ve been validated by the world’s leading health agencies and are backed by rigorous, peer-reviewed science. In many ways, they represent the next logical leap in food safety: faster, smarter, more precise, and scalable for the global food economy.

Yet despite this incredible promise, several of these technologies remain underused—not because they’re flawed, but because they sound unfamiliar. Terms like “irradiation,” “high-pressure processing,” or “digital traceability” can be off-putting to consumers unfamiliar with the science behind them. That’s not a reason to slow down. It’s a call to educate, demystify, and embrace the tools that can dramatically reduce illness and improve trust in the system.

Technologies Advancing our Food System

When you pull back the curtain on today’s food safety landscape, the story isn’t one of doom or decline. It’s one of innovation—of brilliant minds developing tools that keep millions of people safe every single day. And the sooner we embrace that story, the stronger our food system will be. Let’s take a look at some of the technologies that will create a more efficient and safer food system:

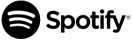

Food Irradiation: A Quiet Powerhouse

Let’s start with one of the most proven—but most misunderstood—food safety interventions. Food irradiation uses ionizing radiation to kill pathogens like E. coli, Listeria, and Salmonella in meat, produce, and spices.

It doesn’t make food radioactive or nutritionally inferior. In fact, both the World Health Organization and the U.S. FDA have endorsed it as safe and effective for decades. A 2022 review in Frontiers in Nutrition confirmed that irradiation reduces pathogen levels by over 99.9% in some foods.

Yet fewer than 0.01% of U.S. grocery items are irradiated, in part due to labeling fears (products must carry a “treated with radiation” statement) and limited consumer understanding.

“We know it works. It’s time to normalize it,” says Dr. Christine Bruhn, a food safety expert at UC Davis. “Like pasteurization, irradiation should be seen as a modern tool, not a threat.”

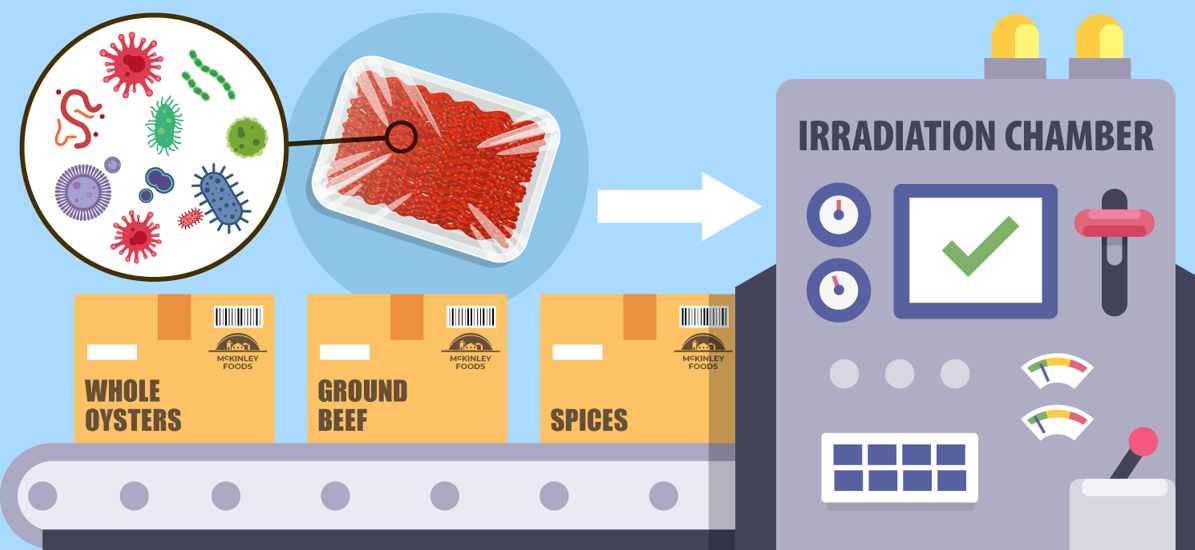

High-Pressure Processing (HPP): Cold, Clean, Effective

HPP is a non-thermal method that uses cold water under extreme pressure to kill bacteria in ready-to-eat foods—no heat or chemicals required. Brands like Suja Juice, Wholly Guacamole, and Boar’s Head already use it to extend shelf life and reduce risk without preservatives.

A 2023 study in Food Control found that HPP extended the shelf life of deli meats up to three times longer, while maintaining safety standards and quality.

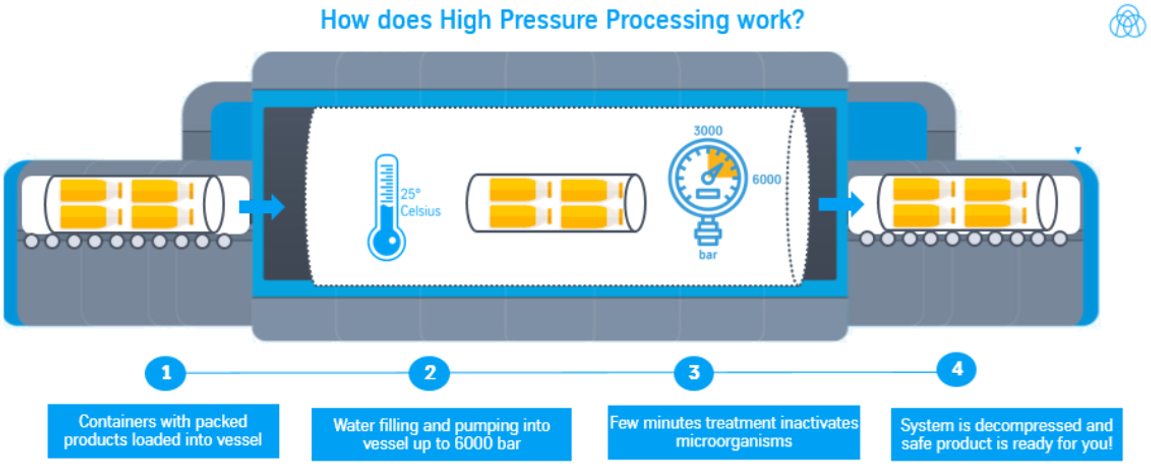

Whole Genome Sequencing (WGS): Tracking Outbreaks at the DNA Level

This powerful tool maps the genetic code of pathogens found in food, allowing scientists to trace outbreaks with precision.

During the 2022 E. coli outbreak in leafy greens, WGS helped CDC investigators pinpoint a contaminated water source on a specific farm—days faster than traditional methods.

During the 2022 E. coli outbreak in leafy greens, WGS helped CDC investigators pinpoint a contaminated water source on a specific farm—days faster than traditional methods.

WGS is now standard in many public health labs, but its continued use depends on consistent funding and cross-agency collaboration.

“It’s the future of outbreak detection,” says Dr. Marc Allard, a senior microbiologist at the FDA. “But it’s not plug-and-play. It requires infrastructure, training, and support.”

Blockchain & Digital Traceability: Speed Matters

When a food recall hits, every minute counts. Traditional traceback methods can take days or even weeks to determine the source of contamination. But in a 2023 pilot by IBM and Walmart, blockchain technology reduced that time to just 2.2 seconds for leafy greens.

Digital traceability systems can also help identify which specific lots are affected—avoiding costly over-recalls and consumer panic.

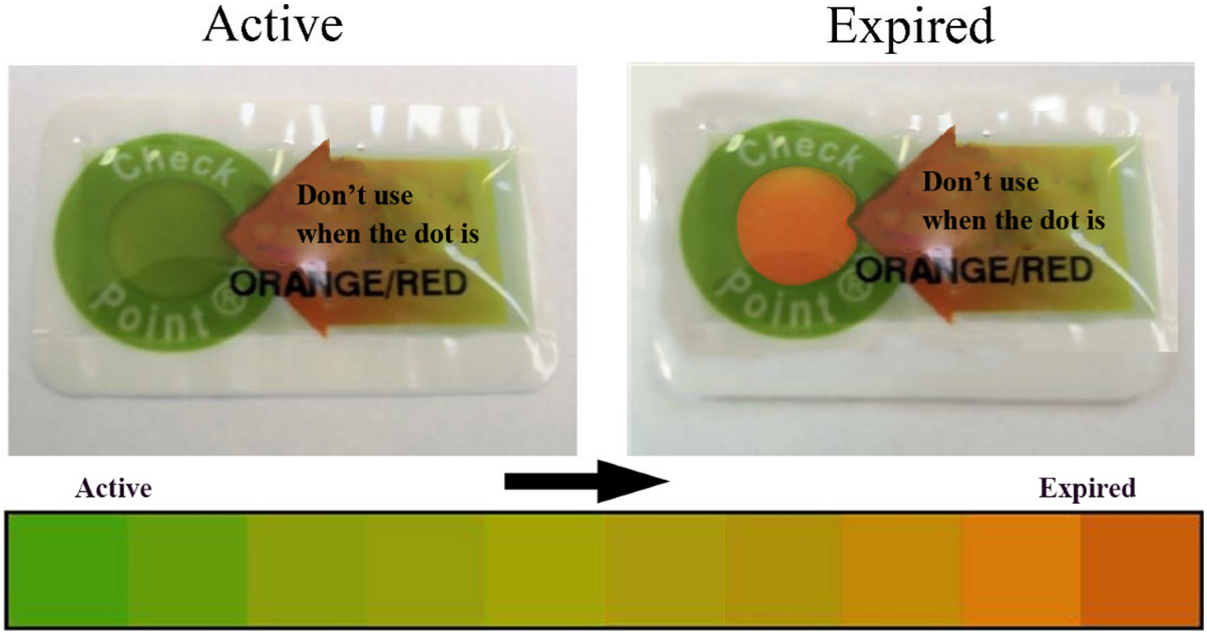

Smart Packaging & Biosensors: Early Warnings Built In

Imagine packaging that changes color when food spoils, or embedded sensors that detect pathogens before the product leaves the facility. These technologies already exist—and they’re evolving quickly.

A 2021 study in Sensors and Actuators B: Chemical demonstrated a biosensor that could detect Salmonella in under two hours—a major improvement over conventional lab tests.

Antimicrobial Interventions in Meat Processing

Foodborne pathogens often originate in raw meat and poultry.

That’s why USDA-approved interventions, like lactic acid rinses and peracetic acid sprays, are used to reduce microbial loads during processing.

A 2023 review in Comprehensive Reviews in Food Science and Food Safety found that these methods can reduce E. coli O157:H7 by up to 90%, especially when used in combination with HPP or chilling systems.

Despite their efficacy, these practices are sometimes misrepresented as “bleach baths.” In reality, they’re a cornerstone of safe meat processing—and far safer than the alternative.

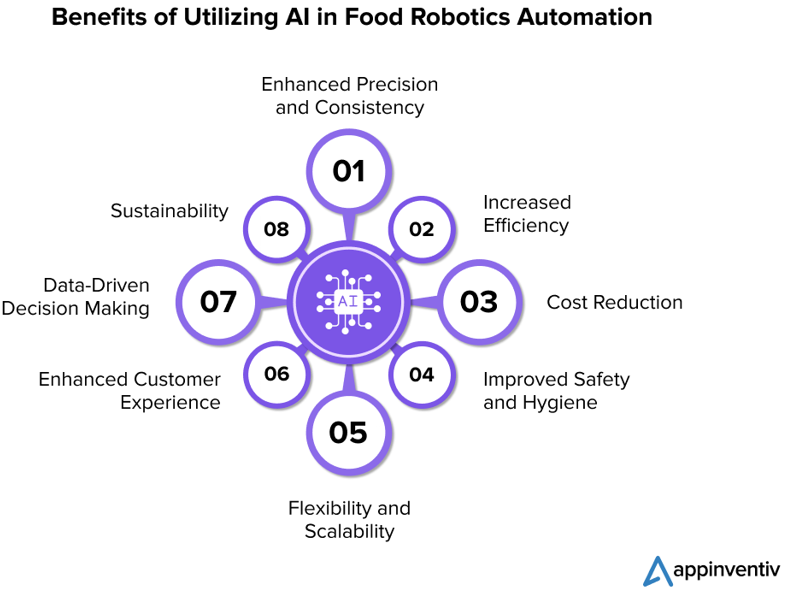

Artificial Intelligence: Smarter, Risk-Based Monitoring

AI is being used to analyze inspection reports, monitor real-time production data, and flag anomalies that human inspectors might miss.

This allows agencies to prioritize inspections based on actual risk, not just routine schedules.

This allows agencies to prioritize inspections based on actual risk, not just routine schedules.

While still developing, machine learning systems have already shown promise in improving predictive analytics for food recalls and contaminant detection.

“AI isn’t about replacing inspectors,” says Dr. Ben Chapman, a food safety researcher at NC State. “It’s about helping them focus where it matters most.”

The Cost of Inaction

Food safety isn’t just about public health—it’s about economic resilience. According to the USDA, foodborne illness costs the U.S. economy more than $17.6 billion annually, factoring in healthcare, lost productivity, and recalls.

One major outbreak can crater consumer confidence and devastate an entire industry. The 2018 romaine lettuce E. coli outbreak, for example, led to a multi-month sales plunge and changes in how leafy greens are grown and labeled.

We can’t afford to fall behind.

Moving Forward: Science, Not Sentiment

We once feared pasteurization. Now it’s non-negotiable. We once worried about refrigeration. Now we trust it implicitly.

Skepticism toward industrial-sounding technology is understandable. But it shouldn’t block solutions that are backed by decades of data and global consensus. These tools aren’t silver bullets, but they are essential allies in an increasingly vulnerable system.

Regulators matter. But so does innovation. If funding realities limit the reach of federal oversight, we must fill the gaps with the best tools available—and that means trusting science over fear.

The Bottom Line

Whether you're a consumer, policymaker, or food producer, the call is the same: support technologies that protect us. Share facts, not fear. And remember—everyone eats. The safety of our food is everyone’s business.

Stalled Trade Deal Threatens U.S. Food System Gains

A carefully negotiated trade agreement between the United States and the European Union could open the door to expanded market opportunities for U.S. farmers and ranchers. But can both sides find a way around the other political disputes that threaten completion of the deal?